|

|

|

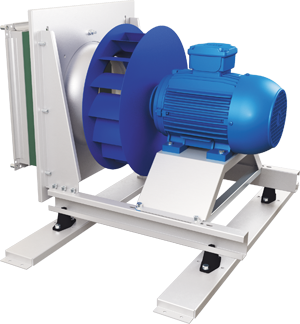

FAN SECTION TYPES:

Plug fan with asynchronous motor (standard); Plug fan with an energy-saving electronically commutated motor (EC motor); Belt driven fan in a spiral casing. Fan sections are equipped with an inspection window.

PLUG FAN Plug fans are used in case of low or medium air performance and pressure. Direct driven motor and backward curved impeller ensures high performance, reliability and easy maintenance due to the absence of belt drive. The impeller is made of high-strength composite material or sheet steel with protective polymer coating. For correct fan operation, soft start, current protection and smooth speed control, it is recommended to use variable frequency drive. It can be supplied loose or mounted inside the fan section as an option. Motor and impeller are isolated from section housing with rubber anti-vibration mounts and flexible duct connectors. The engine complies with energy efficiency classes IE1, IE2, and IE3, depending on the project requirements. As an option the fan can be delivered in EX-proof realization.

|

|

|

PLUG FANS WITH ENERGY-SAVING ELECTRONICALLY COMMUTATED MOTORS (EC MOTOR)  Electronically commutated direct current motors (EC motors) with an external rotor, equipped with a backward curved impeller, are used. Such motors are the most progressive solution for energy saving. EC motors are characterized by high performance throughout the whole range of rotation speed. The advantage of an electronically driven motor is its high energy conversion efficiency (up to 90 %). Electronically commutated direct current motors (EC motors) with an external rotor, equipped with a backward curved impeller, are used. Such motors are the most progressive solution for energy saving. EC motors are characterized by high performance throughout the whole range of rotation speed. The advantage of an electronically driven motor is its high energy conversion efficiency (up to 90 %).

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

SOUND ATTENUATORS: Silencer unit consists of easily removable sound-absorbing 100 mm thick panels, with the length of 600 mm or 1200 mm. Noise absorption is in accordance to ISO 7235. Sound absorbing panels are available in two variants: pointed, with reduced resistance and rectangular, with a larger area of sound absorption. Panels are made of high density mineral wool with protection felt cover.

THE DISTANCE BETWEEN THE PLATES: 100 mm (standard); 150 mm – lowered air pressure drop; 75 mm – increased noise reduction.

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

AIR FILTERS Units include the following filter elements: Panel-type preliminary filters, G3 and G4 class, in accordance to EN779. Filter depth is 50 mm. Reinforced with a steel mesh. Panel frame is made of galvanized steel. Pocket filters with pocket depth of 300 and 600 mm; G3, G4, F5 (M5), F7 or F9 class in accordance to EN779. High efficiency filters: EPA – filters (E10-E11) and HEPA – filters of classes H12-H14, in accordance to EN1822. Filters, based upon active carbon (unlike the filters of other types) are used for absorption of unpleasant ordour, gases and toxic evaporations. All filters have easily removable cassettes that can quickly and easily be replaced. In the case of two stages of filtration, unit contains a compact section in which panel and pocket filters are installed close to each other.

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

ELECTRIC HEATER

Section consists of electric tubular heating elements (heaters) with spiral fins, which are set (in sufficient quantity) into removable cassette frames, made of galvanized steel. Heaters are protected from overheating by thermal switches with automatic reset to + 50 °C and with a manual reset to + 90 °C. Heaters are grouped according to the «triangle» scheme, three heaters in each group. Groups of heaters are then connected in parallel into 380 V power supply network.

OPTION: Unit with a built-in electric heater triac controller allows keeping the supply air temperature at a set level with accuracy of ± 1 °C.

RECOMMENDED ACCESSORIES: Fan Pressure switch DTV 500 – additional protection from overheating in case of low air flow. The sensor can be pre-mounted inside unit, or supplied loose as a separate item. External Triac controller RNS provides smooth control of heaters up to 75 kW (25 kW triac + two steps to 25 kW).

|

| |

|

|

| |

|

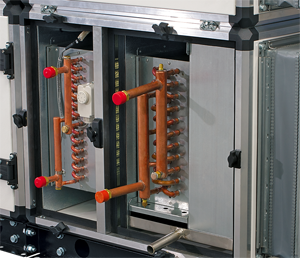

WATER COOLING COIL

Heat exchanger complies with EN 13053, EN 1216. Unit consists of copper tubes with aluminum finning. Section is equipped with a removable drain pan. For water or glycol mixtures up to 50 % glycol concentration. Maximum working pressure of the cooling medium is up to 16 bar (1.6 MPa). Drain and air bleeder valves are provided for each coil.

RECOMMENDED ACCESSORIES: Three-way valve with electric actuator.

|

| |

|

|

|

|

DX COOLING COIL

Complies with EN 13053, EN 1216. Copper tubes with aluminum finning. Section is equipped with a removable drain pan made of stainless steel. For refrigerants R22, R407, R410A, and others. Drain and air bleeder valves are provided for each coil.

WATER HEATING COIL

All heaters comply with the standards EN 13053, EN 1216. Heat exchanger consists of copper tubes with aluminum finning. Maximum temperature of heat transfer fluid: 150 °C. For water or glycol mixtures up to 50 % glycol concentration. Maximum operating pressure of the heat transfer fluid is up to 16 bar (1.6 MPa). Drain and air bleeder valves are provided for each coil.

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

ROTARY HEAT EXCHANGER

A rotary heat exchanger is a rotating cylinder, filled with the layers of corrugated aluminum ribbon. The ribbon is placed so, as to allow supply and extract air flows pass through it. As a result, the ribbon is heated and cooled in turns, thus conveying heat and moisture from the warm air flow to the cold one. The advantages of a rotary regenerator are: high efficiency, keeping comfortable humidity and low risk of frosting. Rotary regenerators in BlauAir units are of two types: Condensation type (standard); Enthalpy type. The additional hygroscopic coating is applied to the tape, which provides additional moisture transfer from one stream to another. This feature is especially useful when using a rotor in summer in combination with the air conditioning system.

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

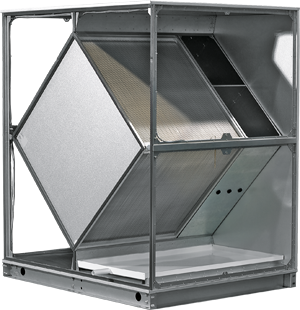

PLATE HEAT EXCHANGER

A plate heat exchanger is a heat exchanger, transferring heat from the exhaust air flow to the outdoor supply air flow. Heat exchanger is made of profiled aluminum plates, packed with elastic heat-resistant sealant. The sealing provides a reliable separation of supply and exhaust air, not allowing moisture, dirt, and microorganisms to transfer between flows. To avoid frosting, the heat exchanger provides active protection by means of the bypass channel. Drain pan is installed under the heat exchanger.

|

x

x

x

x

x

x